Print Capabilities

- Up to 8 color spot

- 4 color process plus up to 4 spot

- Water based inks

- Printed bags and Rollstock

- High speed state of the art flexographic presses

- Spectrometer based PMS color match

- In-house art/graphics department

Bag and Service Capabilities

- Staple pack bags

- Special header card staple packs

- Hangholes (multiple shapes and sizes)

- Metal eyelet hangholes

- Bottom Seals bags

- Sideweld bags

- Mixed seal / Lemo seal bags

- Tear off receipts

- Sleeves

- Vents (single to special patterns in variety of sizes)

- Thumb notch

- Door knob holes (multiple sizes)

- Dicut handles

- Reinforced Fold over dicut handles

- Serrations / Perferations

- Back pouches (3 wall bags with or without hood)

- Compartment bags

- Consecutive numbering

- Special packing (inner bagging)

- Coextruded Mailers

- Custom boxes for best fit

Sample Program

Request a free sample pack! We have thousands of hand-made samples from previous jobs that we can access for similar jobs.

Summit Plastics

Clear View Packaging is part of Summit Plastics. Summit is a high-quality custom extrusion company. Two domestic manufacturing facilities with one vision to provide the best employment and client experience.

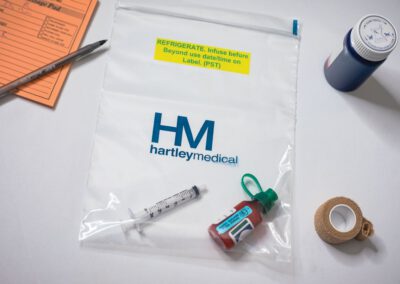

Sampling of Brands Serviced

Clearview manufactures custom packaging for a wide array of companies. We work to help companies achieve their material, construction, appearance, and protection packaging goals.

Quality Certifications

GMP Certified

SQF

Our partner company Summit Plastics has also achieved a 3rd party certification. For details visit their site by clicking the link below.

Lowe’s Certified Printer

ClearView Packaging has completed a packaging printer evaluation for Lowe’s certification. We have achieved full certification status.

Need a Custom Solution?

We like to push the limits to expand our custom capabilities. We will work together to try to make your custom request or help find a source for you.

Materials

Custom blends and options available based on need and application

We stock a wide variety of materials providing for low and high volumes and faster leadtimes

Most materials are FDA approved

Markets Served

Food

Medical

Agricultural

Retail

Industrial

Promotional